- Mechanical Press

- HPP-P series full-automatic powder compacting press

- HPP-P series full-automatic powder compacting press

- HPP-S series full-automatic powder compacting press

- HPP-T series full-automatic powder compacting press

- HPP-N series full-automatic powder compacting press

- HPP-F series full-automatic powder compacting press

- HPP-H series full-automatic powder compacting press

- 500T Full Automatic Mechanical Powder Compacting Press

- HSP series precision machine

- Frame series

- Automation

- HPP-P series full-automatic powder compacting press

- Fishing net machine

- Netting machine

- ZRU-L For U Knot Machine |ZRD-L For Single &Double Knot Machine|ZRU-L For Single Knot Machine

- ZRS-N For Single Knot Machine |ZRD-N For Single &Double Knot Machine

- ZRD-M For Single &Double Knot Machine |ZRS-M For Single Knot Machine

- ZRD-A For Single &Double Knot Machine

- ZRS-H For Single Knot Machine

- ZRD-Y For Single &Double Knot Machine

- ZRS-X For Single Knot Machine|ZRD-X For Single &Double Knot Machine

- Stretching machine

- Twisting machine

- Extruder

- Spare parts

- Dehydrator

- Dyeing machine

- Thread gathering machine

- Fishing net packing machine

- Yarn tester machine

- Net inspection and repairing machine

- Netting machine

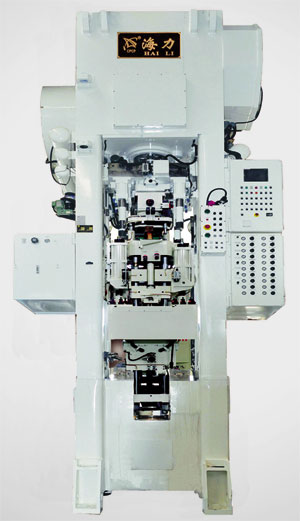

HSP-P series full-automatic PM sizing machine

Application

Our HSP-P series full-automatic PM sizing machine, which suit for PM parts sizing industry, especially complicated multi-step PM parts.

Characteristic

- Our machine is designed and manufactured according to the most advanced national technology. It has characteristics of high precision, multi-function, easily operating, easily maintenance and so on.

- The sizing machine has mechanical structure. The pressing method is relying on the movement of upper sliding pillar. The die is fixed type, and the parts are ejected by lower punch.

- In the sizing operation process, the movements of lower one plate and lower two plate are controlled by ejection rod.

- The lower one punch, lower two punch, core rod and upper inner punch all can be adjusted, which can save the mould cost a lot.

- The multi-level sizing die set, which reduce the following operating procedures and save the cost. It can size multi-level and complicated PM parts.

- Our machine use PLC and touch screen. It is convenient to adjust the display, setting and control of machine running angles.

- Our machine can add other functions depend on our clients’ requirements.

Main machine specification