- Mechanical Press

- HPP-P series full-automatic powder compacting press

- HPP-P series full-automatic powder compacting press

- HPP-S series full-automatic powder compacting press

- HPP-T series full-automatic powder compacting press

- HPP-N series full-automatic powder compacting press

- HPP-F series full-automatic powder compacting press

- HPP-H series full-automatic powder compacting press

- 500T Full Automatic Mechanical Powder Compacting Press

- HSP series precision machine

- Frame series

- Automation

- HPP-P series full-automatic powder compacting press

- Fishing net machine

- Netting machine

- ZRU-L For U Knot Machine |ZRD-L For Single &Double Knot Machine|ZRU-L For Single Knot Machine

- ZRS-N For Single Knot Machine |ZRD-N For Single &Double Knot Machine

- ZRD-M For Single &Double Knot Machine |ZRS-M For Single Knot Machine

- ZRD-A For Single &Double Knot Machine

- ZRS-H For Single Knot Machine

- ZRD-Y For Single &Double Knot Machine

- ZRS-X For Single Knot Machine|ZRD-X For Single &Double Knot Machine

- Stretching machine

- Twisting machine

- Extruder

- Spare parts

- Dehydrator

- Dyeing machine

- Thread gathering machine

- Fishing net packing machine

- Yarn tester machine

- Net inspection and repairing machine

- Netting machine

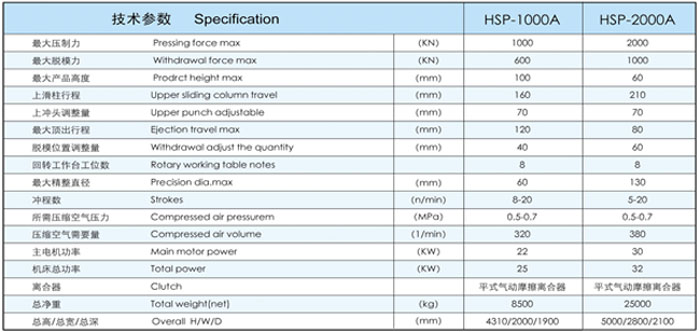

HSP-JZ series full-automatic powder metallurgy products sizing presses

【 Application 】

HSP series of sizing presses are suitable for axle box,step powder metallurgy products to shape.

【 Characteristics 】

(1) The sizing press is designsd with reterece of the latest tech nology of the word-class powder production machines.The sizing technology of themachines follows world trend.

(2) It is mechanical press.Pressing-force depends on the move ment of upper sliding column,while the dieis fixed,which adopts lower punch ejection withdrawal fumction.

(3) The usage of the tool adaptor greathy decreased the replacing time of tooling and for easy&fast setup.

(4) With 12 holes turnplate filling system,convenient filling of tem plate,adjusting and operation,therefore realize its automatic prsduction.

(5) The turnplate with automatic testing device can check idle pressing and overlap pressing as well as whether tested prod ucts be ejected or not.

(6) The usage of turnplate automatec location device and safly clutch can effectively prevent the damage of products,turnplate and tooling as well.

(7) The press adopts PLC and touch screen system which are convenient for the operation angle displaying,setting and con trolling.

(8) Lots of components with world-famous brands guaranteed safety operation and reliable working thereby.

(9) The machine is compact,low naintenance,easy operation and high automation.

(10) Additional functions are available for option,i,e. deburring device vibrating plate feed device for customer’s requirement.

(2) It is mechanical press.Pressing-force depends on the move ment of upper sliding column,while the dieis fixed,which adopts lower punch ejection withdrawal fumction.

(3) The usage of the tool adaptor greathy decreased the replacing time of tooling and for easy&fast setup.

(4) With 12 holes turnplate filling system,convenient filling of tem plate,adjusting and operation,therefore realize its automatic prsduction.

(5) The turnplate with automatic testing device can check idle pressing and overlap pressing as well as whether tested prod ucts be ejected or not.

(6) The usage of turnplate automatec location device and safly clutch can effectively prevent the damage of products,turnplate and tooling as well.

(7) The press adopts PLC and touch screen system which are convenient for the operation angle displaying,setting and con trolling.

(8) Lots of components with world-famous brands guaranteed safety operation and reliable working thereby.

(9) The machine is compact,low naintenance,easy operation and high automation.

(10) Additional functions are available for option,i,e. deburring device vibrating plate feed device for customer’s requirement.

【 Technical Specification 】