- Mechanical Press

- HPP-P series full-automatic powder compacting press

- HPP-P series full-automatic powder compacting press

- HPP-S series full-automatic powder compacting press

- HPP-T series full-automatic powder compacting press

- HPP-N series full-automatic powder compacting press

- HPP-F series full-automatic powder compacting press

- HPP-H series full-automatic powder compacting press

- 500T Full Automatic Mechanical Powder Compacting Press

- HSP series precision machine

- Frame series

- Automation

- HPP-P series full-automatic powder compacting press

- Fishing net machine

- Netting machine

- ZRU-L For U Knot Machine |ZRD-L For Single &Double Knot Machine|ZRU-L For Single Knot Machine

- ZRS-N For Single Knot Machine |ZRD-N For Single &Double Knot Machine

- ZRD-M For Single &Double Knot Machine |ZRS-M For Single Knot Machine

- ZRD-A For Single &Double Knot Machine

- ZRS-H For Single Knot Machine

- ZRD-Y For Single &Double Knot Machine

- ZRS-X For Single Knot Machine|ZRD-X For Single &Double Knot Machine

- Stretching machine

- Twisting machine

- Extruder

- Spare parts

- Dehydrator

- Dyeing machine

- Thread gathering machine

- Fishing net packing machine

- Yarn tester machine

- Net inspection and repairing machine

- Netting machine

HPP-T series full-automatic powder compacting press

【 Application 】

HPP-T series of presses are suitable for powder metallurgy, fine ceramics,magnetic materials and relevant industry what need powder to suppress it,the powder products of the especially complicated form aredone and keep compacting automatically.

【 Characteristics 】

(1) This machine is a typical double eccentric connecting rod mechanism, suppressing a constant position, gear drive, low noise, stable and reliable.

(2) The machine uses mechanical force floating female molds can be suppressed to achieve non-simultaneous three times, or pre-press, press simultaneously, the top pressure to ensure the suppression of uniform density, size and same weight.

(3) on the convex mold a pre-loading mechanism, and ejection protection, and adjustable force and stroke, to avoid cracking of rough ejection.

(4) pressed by stroke, ejection stroke, the top compression stroke and other parameters can be adjusted continuously, and a calibration instruction can meet the needs of different blank shape adjustment.

(5) Many types of die machine can be configured to meet the five basic types of blank pieces of molding.

(6) machine with intelligent human-machine interface, touch screen, using a large number of advanced technology and imported components, ensure that the machine operation, safety and reliability.

(7) compact structure, operation, convenient adjustment, high degree of automation.

(8) In addition to the machine itself functions, you can also add some features, such as manipulator.

(2) The machine uses mechanical force floating female molds can be suppressed to achieve non-simultaneous three times, or pre-press, press simultaneously, the top pressure to ensure the suppression of uniform density, size and same weight.

(3) on the convex mold a pre-loading mechanism, and ejection protection, and adjustable force and stroke, to avoid cracking of rough ejection.

(4) pressed by stroke, ejection stroke, the top compression stroke and other parameters can be adjusted continuously, and a calibration instruction can meet the needs of different blank shape adjustment.

(5) Many types of die machine can be configured to meet the five basic types of blank pieces of molding.

(6) machine with intelligent human-machine interface, touch screen, using a large number of advanced technology and imported components, ensure that the machine operation, safety and reliability.

(7) compact structure, operation, convenient adjustment, high degree of automation.

(8) In addition to the machine itself functions, you can also add some features, such as manipulator.

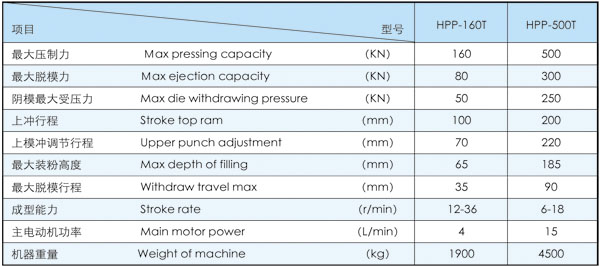

【 Technical Specification 】